Chrome ore is a strategic raw material widely used in the metallurgical industry. Its beneficiation process directly affects the corrosion resistance and mechanical strength of special steel products.

Due to complex mineral textures and diverse associated minerals, it is essential to apply scientific and efficient methods. An optimized chrome ore process is key to improving purity and industrial value.

Aluminous Chromite

This ore mainly contains chromite, aluminum, chromium, and iron. Its complex chemical composition increases the difficulty of processing. However, it also holds high industrial value.

Magnesian Chromite

It coexists with chromite. It contains magnesium, chromium, and iron. The intergrowth makes the separation process more challenging and must be carefully considered during chrome ore beneficiation.

Chromite (FeCr₂O₄)

This is the most important industrial chrome ore. It is weakly magnetic and commonly used in metallurgy.

High-Chrome Spinel and Hard Chrome Spinel

These ores contain 32%–50% Cr₂O₃. They have similar physical properties to chromite and are of magmatic origin.

High Hardness and Brittleness

Chrome ore has a Mohs hardness of 5.5 to 6.5. During grinding, over-crushing often occurs. It is recommended to use wear-resistant equipment.

Fine Grain Size Distribution

Many chrome ores have uneven dissemination. A large portion is in fine particles. In most cases, over 60% must be ground to -200 mesh for full liberation.

Harmful Elements

Some ores contain sulfur and phosphorus. These elements must be removed during the chrome ore beneficiation process to reduce pollution in later stages.

Crushing and Grinding

Jaw crushers and cone crushers are used for coarse crushing. Ball mills or rod mills are applied for grinding. The aim is to fully liberate the chrome minerals.

Gravity Separation and Magnetic Separation

Separation is based on density. Chromite has a specific gravity of 4.0 to 4.8. Jig machines and shaking tables are used to separate particles. Wet or dry magnetic separators remove magnetic gangue minerals.

Flotation

This is used for fine particles or ores with complex intergrowth. pH levels are adjusted and collectors such as fatty acids are added for better separation.

High Energy Consumption

Traditional equipment is energy-intensive. Crushing and grinding alone consume 30%–40% of the total energy in the plant.

Low Recovery Rate for Fine Particles

Gravity separation is less effective for particles smaller than 0.074 mm. This limits concentrate grade improvement.

Environmental Concerns

The flotation process uses chemical reagents. These may cause water pollution. Traditional processes often fail to meet modern environmental regulations.

Efficient Crushing Equipment

New crushers like hydraulic cone crushers and impact crushers improve crushing efficiency by 20%. Energy use is reduced by 15%.

Optimized Grinding Parameters

Pulp density should be kept between 65% and 75%. Steel ball sizes should range from 20 to 80 mm. This ensures the ore is ground to the desired fineness.

Stage Grinding and Stage Separation

For complex ores, use a “coarse grind – rough separation – regrind – final concentration” approach. This avoids over-crushing and improves recovery.

New Jig Machines

High-efficiency jigs like sawtooth wave types increase processing capacity by 30%. They also improve separation accuracy by 10%.

Dense Media Separation (DMS)

A suspension of ferrosilicon or magnetite is used as the medium. By controlling the density at 2.8–3.2 g/cm³, precise separation is achieved.

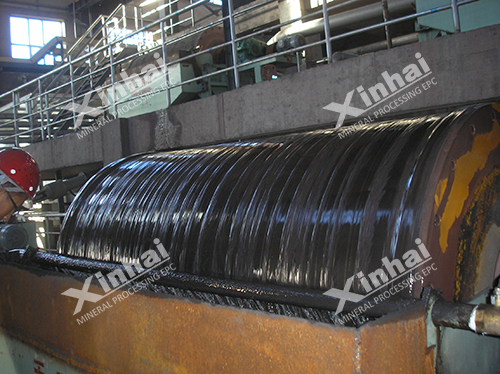

Combined Gravity + Magnetic Process

Gravity separation recovers coarse particles. Magnetic separation follows for fine particles. Overall recovery improves by 5%–8%.

High-Intensity Magnetic Separators

Wet magnetic separators with field strength of 1.0–1.5 Tesla are effective for weakly magnetic chrome ore.

Real-Time Magnetic Field Adjustment

Monitoring systems can adjust magnetic field strength automatically. This adapts to ore property variations.

Magnet + Gravity Combination

After magnetic separation, concentrates are re-treated using shaking tables. The grade of the chrome concentrate can rise from 40% to over 45%.

Eco-Friendly Reagents

Low-toxicity, phosphorus-free collectors (e.g., modified fatty acid esters) reduce reagent usage by 30%. They also minimize environmental damage.

Advanced Flotation Machines

XCF-KYF flotation cells have uniform aeration and higher mixing performance. Flotation efficiency increases by 15%.

Three-Stage Flotation Flow

A flow of roughing, cleaning, and scavenging is used. Middling products are recycled. Chrome recovery rates can exceed 85%.

Applications: Suitable for coarse particles >0.074 mm with distinct density differences.

Main Equipment:

Jig Separators: Handle 10–100 tons per hour. Suitable for 5–0.5 mm particles.

Shaking Tables: Offer high precision. Ideal for 2–0.037 mm particles.

Spiral Chutes: Simple design. Works well for 0.5–0.01 mm particles.

Principle: Based on magnetic susceptibility differences. Chromite ranges from 20–60×10⁻⁶ cm³/g.

Key Equipment:

Permanent Magnetic Drum Separators: For medium-coarse particles (2–0.1 mm). Magnetic field: 0.1–0.3 Tesla.

Wet High-Intensity Magnetic Separators: For fine particles (0.1–0.01 mm). Field strength: 0.8–1.5 Tesla.

Best Use Case: Suitable for fine particles <0.074 mm and complex ores with close densities.

Equipment Options:

SF or JJF Mechanical Flotation Cells: Self-aerating. Ideal for small or mid-sized plants.

KYF Pneumatic Cells: Require external air. Suitable for large-scale plants with high processing capacity.

Typical Flow:

Gravity separation recovers coarse chrome concentrate.

Magnetic separation handles tailings to recover fine particles.

Flotation is applied to magnetic tailings for further recovery.

Mobile jaw crushers are self-contained, high-performance units designed for primary crushing in open‑pit mines, construction, recycling, and foot-of-pit gold operations.

Magnetic separators play dual roles in mining. It protects equipment from tramp metal and recovering valuable minerals or removing magnetic impurities from ore