Since established in 1997, Xinhai always be at the forefront of the global gold industry, who has been committed to the research and development of cyanide gold process, technology and equipment, after 20 years of research, Xinhai has formed a set of efficient, environmental, energy-saving and economic Xinhai gold processing equipment.

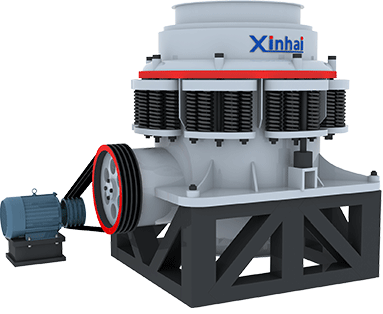

Using exogenic process to break up large pieces of gold ore, which overcome their internal intermolecular force and gradually reduce gold ore granularity until to a certain size, which can provide appropriate particle size of gold ore for separating operation. The quality of crushing directly affects gold extracting technology and economic indicators.

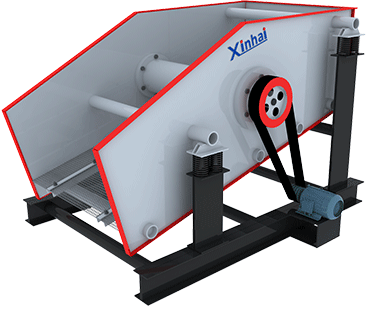

Using screen to divide gold ore into several levels according to the particle size, then screening the fine particle of the gold ore from feeding, which increase the productivity of Xinhai crusher and avoid over crushing problem.

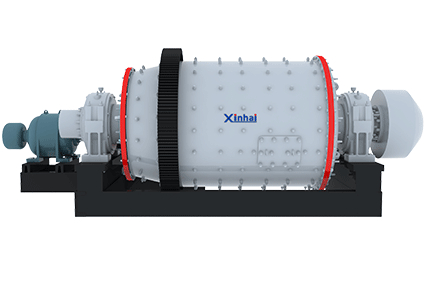

Grinding is the next step of mill process, and is the last process before the separation operation. To make the gold ore achieve individual separation completely or basically, at the same time, as far as possible to avoid over grinding, provide gold ore pulp with appropriate particle size and concentration for separation operation, creating better conditions for gold recovery.

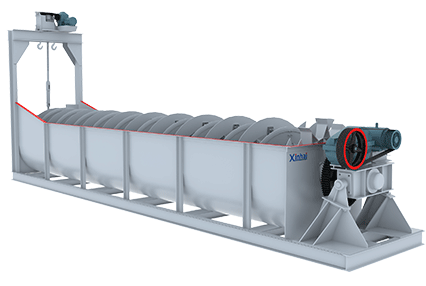

Separating standard fine grain before gold ore is sent to the grinder. Then separate the rough grain from ore discharge of grinder, then return to the grinder. Classification can separate the standard gold grain from the grinder discharging in time, avoiding needless grinding, and send to separate operation early.

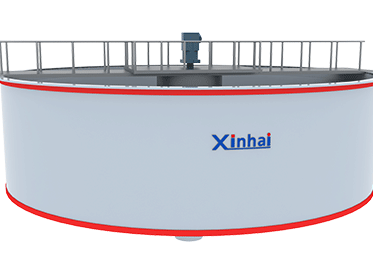

After crushing and screening, grinding and classifying, gold ore is sent to agitation tank for pulp stirring, then after add Xinhai special activated carbon to achieve counter current absorption, gold loaded carbon passed by desorption electrolysis system and get gold mud after electric shocks, then gold loaded carbon carry on recycling operations, finally leach the pulp and get gold concentrate.

After crushing and screening, grinding and classifying, gold ore is sent to agitation tank for pulp stirring, then sent to Xinhai flotation cell for gold flotation process, finally get the gold concentrate after thickening and dewatering.

After crushing and screening, grinding and classifying, gold ore is sent to agitation tank for pulp stirring, then sent to Xinhai jig, shaking table or mixing equipment for gold gravity separation process, finally get the gold concentrate after thickening and dewatering.

The gold ore particles are deposited from the pulp by gravity or centrifugal force, which can concentrate the tailings pulp and recycle some water as recycle water; And it can also be used as gold concentrate dewatering before filtering, improving the grade of gold concentrate and filter effect.

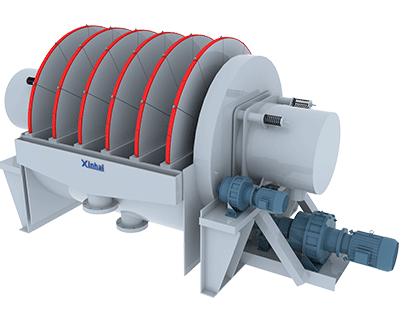

Filtering is the next step of thickening, it relies on filtering medium (filter cloth) and pressure difference to make gold ore pulp achieve solid-liquid separation in porous filter medium (such as filter cloth), and make the concentrations of gold concentrate and tailings reach standard. For example, gold concentrate moisture can be reduced from 45-60% to 10-18%.

Xinhai has make Class B design Qualification, set up mine design institute and mineral processing research institute, more than 200 professionals provide the technical support service for the extraction of gold, Since its establishment 20 years, Xinhai has been committed to the development and innovation of process and equipment used in the extraction of gold, and has formed the complete extraction of gold system. Xinhai concentrates on providing the Turnkey Solution for Mineral Processing Plant that is research and design- complete equipment manufacturing and procurement- commissioning and delivery”, striving for building the international leading enterprise in the extraction of gold.

"Create a global brand, based on global gold markets " has been one of the strategic thought of Xinhai, depending on its professional gold processing service, Xinhai has got the EU certification, and ISO9001:2015quality management system certification, Xinhai is classified as the assured brand with advanced products and standard quality!

Xinhai currently has many patents technologies, the extraction of gold plants spread among China, Southeast Asia, South America, Africa, Russia, Mongolia, North Korea and other places, and Xinhai has established offices around the world.

Please leave your message here! We will send detail technical info and quotation to you!