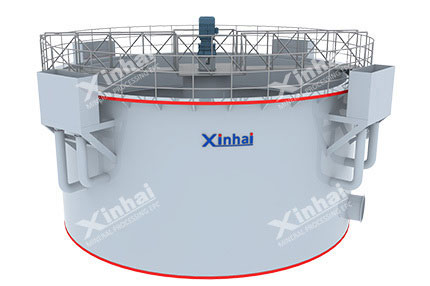

[Introduction]: Washing thickener for solid-liquid separation of gold leaching liquid

[Capacity]: 10-250t/d

[Improvement]: 1, Countercurrent washing, large capacity and high washing efficiency; 2, Small area taken; 3, Stable production and convenient operation.

Xinhai washing thickener includes two layers washing thickener and three layers washing thickener. Taking the three layers washing thickener as an example. The pulp is fed by a feeding tube, and the pulp that settles freely in the rake area is further concentrated by the pressure of the scraper blade, gradually scraped towards the center of the pond, then enters the next layer pond through the mudding slot. The clear water is entered into the lowest layer for washing the material through the distribution box, the bottom of overflow is returned to the upper layer for washing the material through the distribution box. The overflow of the first layer is discharged through the downflow dam, and the material after two times of washing is discharged through the bottom.

Spec. | Diameter | Depth of Center Tank (m) | Subsidence Area (m2) | Revolution of Harrow Frame (r/min) | Capacity | Motor Model | Motor | Weight | Remarks |

2NZS6 | 6 | 5.34 | 56.5 | 0.25 | ≤ 50 | Y112M-6 | 2.2 | 13360 | Excluding the pond weight |

2NZS7 | 7 | 5.41 | 77 | ≤ 56 | 14200 | ||||

2NZS8 | 8 | 6.08 | 100.7 | 0.28 | ≤ 68 | Y132M1-6 | 4 | 50449 | Including the pond weight |

2NZS9 | 9 | 5.91 | 127.3 | ≤ 88 | 54628 | ||||

2NZS12 | 12 | 6.87 | 226 | 0.2 | ≤ 160 | Y132M2-6 | 5.5 | 40400 | Excluding the pond weight |

2NZS15 | 15 | 6.95 | 353.3 | 0.15 | ≤ 250 | 51470 |