Gold mining isn’t just for the corporate giants anymore—small and medium-sized enterprises (SMEs) are staking their claim, hunting for ways to turn raw ore into real profits without needing a fortune to start. With gold prices bouncing around and environmental rules getting stricter, the challenge is clear: find practical, affordable, and scalable methods that don’t leave the land scarred or your bank account empty. This guide is built for the little guy—real-world advice from folks who’ve been there, covering the how-to’s, the gear, and the wins that prove SMEs can process gold and grow without going broke.

Gold’s always in demand—whether it’s sparkling on a necklace, powering a smartphone, or sitting in an investor’s vault. But for SMEs, jumping into the game is no walk in the park. Cash flow’s tight, permits can feel like a full-time job to secure, and keeping operations humming takes more than pocket change. You’re stuck juggling the need to pull decent gold yields with the reality of limited funds, all while staying on the right side of environmental regulators. This isn’t some academic exercise—it’s about solutions that work for growing businesses trying to make it without sinking under debt.

I’ve talked to small operators who’ve been through the grind—folks like Mike, a third-generation miner in Nevada, who told me, “You don’t need a million bucks to start; you need a plan that fits your ore and your wallet.” That’s the heart of this guide: practical know-how rooted in experience, not hype.

Let’s get down to business. Here are the best ways SMEs can process gold ore without needing a Wall Street budget. These aren’t pie-in-the-sky ideas—they’re methods real operators swear by.

Gravity Separation: Cheap and Solid

If your ore’s got visible gold nuggets or coarse particles and isn’t bogged down with sulfides, gravity separation is your go-to. It’s as old-school as it gets: you use the weight of gold to pull it out of the muck. Picture a centrifugal concentrator spinning fast to grab the heavy bits, a shaking table rattling away to sort the gold clean, or a simple sluice box snagging the shiny stuff as water rushes through. It’s not fancy, but it works—recovery rates can hit 60-90% if your ore cooperates.

The beauty? It’s cheap. You can snag decent gear for $5,000 to $20,000, depending on scale. I’ve seen guys in placer country pay off their setup in months because they kept it simple. No crazy chemicals, no big power bills—just gravity doing the heavy lifting. Test your ore first, though—fine gold or sulfide-heavy stuff won’t play nice.

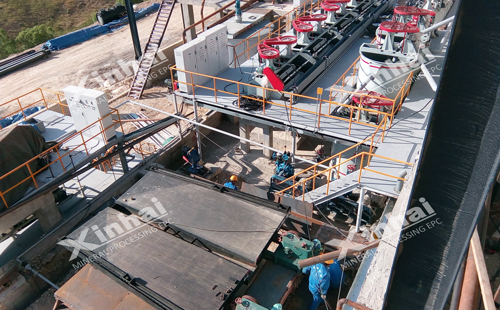

When gold’s locked up tight in sulfides, flotation steps up. It’s a bit like fishing with bubbles: you mix in some reagents, churn the ore in water, and let air bubbles float the gold-rich minerals to the top. It’s perfect for complex ores that gravity can’t crack. For SMEs, small flotation cells keep costs down—think $10,000 to $50,000 for a basic setup. Look at brands like Xinhai Mining for reliability, or scout local suppliers for budget-friendly options—just make sure you run trials to avoid lemons.

Pro tip: keep reagent costs low by experimenting with generics. A buddy of mine in Colorado cut his chemical bill by 30% tweaking the mix—small wins add up. Flotation’s not the simplest, but it’s a game-changer for tricky ores.

Cyanide’s been the gold-leaching champ for decades—methods like Carbon-in-Pulp (CIP) or Carbon-in-Leach (CIL) pull gold out reliably. But it’s not cheap, and regulators are all over it because of the toxic waste. For SMEs, the startup costs—tanks, agitators, carbon systems—can hit $15,000 and climb fast. Plus, one spill, and you’re toast.

That’s why alternatives like thiosulfate or chlorine leaching are worth a look. They’re safer, often cheaper, and less likely to land you in hot water. A small outfit in South Africa I heard about switched to thiosulfate and slashed their waste cleanup costs by half. You’ll still need tanks and reactors (starting around $15,000), but the payoff’s in the long game—less hassle, lower risk.

Now, this one’s a bit out there: using bacteria to eat your ore and free the gold. It sounds crazy, but it’s real—and dirt-cheap for low-grade piles big operations ignore. We’re talking pennies per ton if you get it right. The catch? It’s slow. You need warm weather, patience, and a knack for keeping the bugs happy. I read about an Aussie crew who doubled their profits bioleaching tailings—stuff nobody else wanted. It’s not for everyone, but if you’ve got time and cheap land, it’s a sleeper hit.

You can’t process gold with good intentions—you need tools. Here’s what SMEs should prioritize and how to get it without selling the farm.

Crushers and Grinders: Ore’s gotta be small to process. A jaw crusher ($3,000-$10,000) and ball mill ($5,000-$20,000) are your basics. Buy used from mining auctions—check sites like Ritchie Bros.—and save 50% if you’re handy with repairs.

Gravity Gear: Shaking tables or concentrators like the Falcon or Knelson run $5,000-$15,000. Look for deals in mining hubs like Denver or Perth.

Flotation Cells: Small units start at $10,000. Local fabricators can build custom ones cheaper—just spec it right.

Leaching Tanks: Steel or plastic, $5,000-$20,000. Secondhand chemical tanks work if they’re clean.

Power: Solar’s dropping in price—$10,000 for a small array beats diesel in sunny spots.

Talk to other operators. A guy I met in Idaho scored a used concentrator for $2,000 because he asked around. Networks beat catalogs every time.

Take Sarah, who runs a 10-man crew in Ghana. She started with a $15,000 gravity setup—sluices and a concentrator—and pulled 80% recovery from alluvial ore. Two years in, she’s scaled to flotation for deeper sulfides, doubling output without doubling costs. Or look at Juan in Peru: he went thiosulfate on a $20,000 budget, dodging cyanide headaches, and now exports to jewelers in Europe. These aren’t flukes—they’re proof SMEs can win with the right approach.

Processing gold on a budget isn’t about cutting corners—it’s about picking the right fight for your ore, your cash, and your goals. Gravity’s quick and cheap, flotation cracks tough nuts, leaching scales up, and bioleaching’s the dark horse. Gear’s out there if you hustle for it. The key? Test your ore, talk to folks who’ve done it, and don’t bet the house on one shiny idea. SMEs can carve out a piece of the gold game—it’s not easy, but it’s doable. Dig in.

China ranks second globally with 3.44 billion tons of phosphate reserves, yet faces significant quality challenges. 85% of deposits are sedimentary-type, with over 90% concentrated across Yunnan, Guizhou, Hubei, and Sichuan provinces. High-grade ore (P₂O₅≥30%) constitutes less than 20% of total reserves. This "large but weak" resource structure results in an average national ore grade of 17%, far below resource-rich countries like Morocco. More critically, existing high-grade reserves may only sustain 10-15 years of mining, sounding the alarm for resource depletion.

Silica sand is an essential raw material for various industries, including glass production, foundries, construction, and water filtration. However, raw silica sand typically contains impurities like clay, dust, iron oxides, and oversized particles that must be eliminated to comply with industrial standards. Choosing the appropriate silica sand washing plant is crucial for efficient processing, cost-effectiveness, and high-quality results. This article will outline the important factors to consider when selecting a silica sand-washing plant.