At the beginning of the new year 2020, the “Outstanding Engineers” from China University of Mining and Technology (Xu Zhou) majoring in mineral processing engineering came to Xinhai Mining for 5-day visit and internship leading by Wang dapeng, associate professor, school of chemical engineering, China University of Mining and Technology. They received a warm reception from the chairman Mr.Yunlong Zhang and each department.

In order to let the students have some understanding of Xinhai Mining and relative mineral processing knowledge, the chairman of Xinhai Mining, Mr. Yunlong Zhang and the representatives from each department arranged relative knowledge lessons about e-commerce, mineral processing experiment and design, mine automation control, main mechanical products production processing assembly process and so on. The students also were arranged to visit the research institute, design institute and workshops, to deeply understand the meaning and connotation of Xinhai Mining mineral processing EPC+M+O service.

During the visit, Mr. Yunlong Zhang, the chairman of Xinhai Mining, led and answered the questions about the future career planning, career goals, professional treatment and so on combined with his own career development experience. He also introduced and analyzed about future plan of Xinhai Mining in 5 to 6 years, the “5-transfermation strategy” and innovative processing technology and equipment deeply in details.

The vice president Dapeng Wang aired his own views at scene. He also put forward reasonable suggests about company development. Besides, he also had in-depth discussions with Mr. Yunlong Zhang, chairman of Xinhai Mining, on school-enterprise cooperation, off-campus tutor, “One Belt And One Road” mining training project and scientific research project cooperation, and finally the two sides reached the cooperation intention.

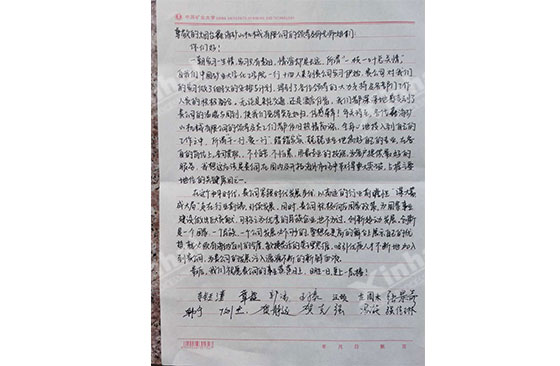

After visit and internship, the students left Xinhai Mining a thanks letter to express their gratitude, and express sincere admiration to the professional technology and service of Xinhai personnels. Some students also put forward the idea of working in Xinhai Mining after graduation at once. The human resources department also communicated with it on the issues related to the contract.

Time is short, but the harvest is abundant. The forward-looking development thinking, innovative technology thoughts, professional service attitude and the warm reception of each department gave a deep impression to the teacher and students of China University of Mining and Technology, which also laid the foundation for the cooperation between Xinhai Mining and China University of Mining and Technology. Later, Xinhai Mining will continue to promote the talent development of xinhai mining outfit and expand the development path of innovation and entrepreneurship of colleges and universities through school-enterprise cooperation.

As one of the common processing equipment for metal and non-metal minerals, agitating flotation cell can be divided into mechanically agitating flotation cell and air-inflation agitating flotation cell. The working principle of them is that: driven by the motor through the triangular belt, the impeller rotates to form the suction suction (or external inflation) of negative pressure slurry, so that the air, medicine and slurry mix, minerals adhere to the bubble surface and float up, forming a mineralized foam layer on the slurry surface, under the condition of relatively constant control of the liquid level, the foam is scraped out with a scrape.

The spiral chute mainly uses the inertial centrifugal force generated by the mineral of different density in the rotating motion of the spiral to separate the heavy and heavy minerals. At present, mineral resources are faced with such unfavorable conditions as depletion, refinement and hybridization, so improving the dressing efficiency of sorting equipment and improving the recovery rate have become the most important task in the development and research of mining industry. This article mainly from three aspects to teach you how to effectively improve the spiral chute dressing efficiency.