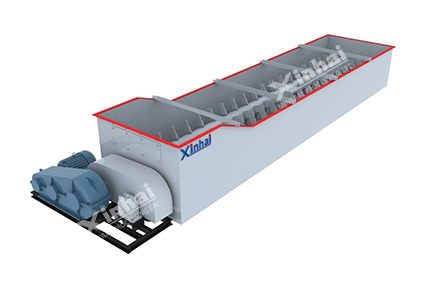

[Introduction]: A mineral washer used for mechanical classification according to the different settling rates of solid particles with different specific gravity in the liquids.

[Capacity]: 35-50t/h

[Improvement]: Xinhai can customize the spiral chute washer according to the actual working conditions and customer requirements.

The double spiral chute washer is composed of a tank body, left and right spiral blade shaft and transmission device. The motor drives the two spiral shafts to produce the relative rotation through the reducer, big and small gears. The blades on the spiral shafts are stagger installation. The material is fed from the lower part of the tank body into the middle of two spiral shafts. The mud mass and the ore particles adhering to the surface of the mud are washed by the high-pressure water fed from the upper part of the tank body according to the blade rubbing and scrubbing, so that the ore mud can be broken and the ore particles are separated. The washed fine mud is discharged by the overflow outlet that installed at the back of the tank body, and the scrubbed ore is transported to the ore outlet at the front of the tank through the rotating spiral blade shaft, and then discharge.

| Model | Lengthe of body(mm) | Width of body(mm) | Production capacity(t/h) | Feed size(mm) | Inclination | Pitch(mm) | Motor | Weight(kg) | |

| Model | Power(kW) | ||||||||

| CXK1566 | 6660 | 1500 | 35-40 | <75 | 10.84° | 300 | Y200L2-6 | 22 | 15800 |

| CXK1676 | 7630 | 1600 | 40-50 | 10° | Y250M-6 | 37 | 17168 | ||