Cyclone separator (Hydrocyclone) is a kind of classification equipment widely used at present because of its high classification efficiency, small floor space and low price. It can be applied in the mineral classification, sewage treatment, slurry concentration, desilting and oil and water separation, etc.

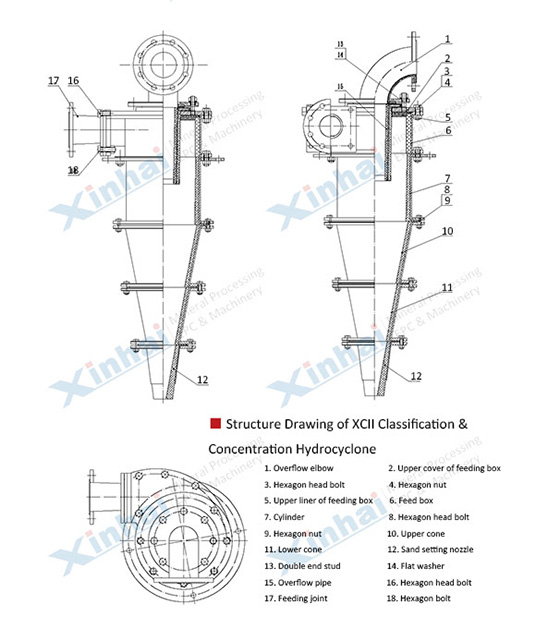

The lower part of the cyclone separator is a conical shell, and the upper part is connected to a cylindrical shell. The upper end of the cylindrical casing is sealed, and a bottom plate is arranged in the middle, and a short pipe overflow pipe is inserted in the center of the bottom plate. A feeding pipe is connected to the lower portion of the bottom plate along the tangential direction of the cylindrical shell surface, and an overflow discharging pipe is connected to the upper portion of the bottom plate along the tangential direction of the casing, and the lowermost end of the cone has are placeable settling nozzle.

The cyclone separator is mostly made of wear-resistant cast iron. In order to reduce the wear speed of the inner wall of the body, it is also often lined with wear-resistant materials, such as wear-resistant rubber. The specifications of the cyclone separator are expressed in terms of the diameter of the cylinder. For example, the diameter of the cylindrical portion of the Φ350 hydrocyclone is 350 mm, and the cone angle of the cone can be different, typically a minimum of 10° and a maximum of 45°.

Cyclone separator is a kind of equipment for classifying or separating materials based on their particle size and density. The material to be classified or separated is fed at a high speed from the inner wall of the cylinder by a tangential line, and the mixture of medium and particles is rotated to form a centrifugal force field which solid materials or liquid phases of different particle sizes and different densities generate different motion trajectories.

Under the action of centrifugal force, medium viscous resistance, buoyancy, gravity and other force fields, coarse particles and large density particles move to the periphery and are discharged from the spigot through the cone; fine particles, low-density particles or liquid phase move to the center and discharge by the overflow tube, thus achieving separation of coarse and fine particle or separation of fluids of different densities.

Cyclone separators are mainly used in the following aspects in mineral processing:

(1) Used as the classification equipment in the grinding circuit, especially for fine grinding;

(2) Used for desliming and concentration of slurry;

(3) Heavy medium hydrocyclones are common heavy media classification equipment.

At present, there are many types of cyclone separator on the market. According to the use function, cyclone separator can be mainly divided into classifying cyclone separator, dewatering cyclone separator, desliming cyclone separator, deslagging cyclone separator and concentrating cyclone separator. The specific application and use phase of cyclone separators are as follow:

Classifying cyclone separator, as its name implies, is to separate and classify the material, such as solid-liquid separation, coarse-fine separation, which is divided into one-stage classification and two-stage classification. One-stage classifying cyclone separators are widely used in the grinding stage of the small and medium-sized processing plants, and forms a closed-circuit grinding and classifying cycle with ball mill. The two-stage classifying cyclone separators are generally used in the second-stage inspection to achieve the function of controlling classification.

The dewatering cyclone separators are mainly used to complete part of the dewatering operation, and the solid-liquid separation cannot be completely realized only by dewatering cyclone separators. The structure of the cyclone separator varies depending on the material being processed.

The desliming cyclone separators are mainly used for material desliming operation.

Deslagging cyclone separators are widely used in power plant wet desulfurization, lime pulping, tap water sand removal, sewage treatment and other operations. It is mainly used to remove coarse sand and impurities of large particle sizes. Higher slag removal efficiency can be achieved with a dedicated deslagging cyclone separator.

The feed port of concentrating cyclone separator has a unique structure, so it is generally not used alone. It is often used together with thickeners, dewatering screens, filters and other equipment to improve dewatering efficiency and achieve concentration of various minerals before filtration. It is also often used in the concentration operation before the flotation and cyanidation operation, as well as the operation of tailings dry stacking.

Concentrating cyclone separator is also used for dewatering in nature. However, the feed port of concentrating cyclone separator has a unique structure, and the concentration of the underflow slurry is larger.

The above are the several aspects about cyclone separator used in the mineral processing. When choosing a cyclone separator, it is recommended to purchase it from the professional and regular cyclone separator manufacturers, and consult professional hydrocyclone technicians according to the actual production conditions to achieve both technical indicators and economic benefits.

Magnetic separation is a common mineral processing method, which realizes the separation in the uneven magnetic field of magnetic equipment according to the magnetic differences among various minerals. Therefore, it is very important to select suitable magnetic equipment to achieve the ideal magnetic separation effect. Here are the types and applications of magnetic equipment in mineral processing.

Agitator tank is indispensable equipment in the froth flotation process. The agitator tank can suspend solid particles in the solution, accelerate the process of chemical reaction, heat transfer, mass transfer, mix and disperse two or more immiscible liquids to obtain a kind of mulsion, mix two or more immiscible liquids to obtain a homogeneous mixture and achieve gas-solution mixing.