While the mineral processing industry was in its early years of development, most mineral processing plants adopted low-level management mode due to the limited economic level and ore beneficiation technology, which not only increased the amount of tailings discharge, but also caused mine resources waste. Nowadays, with the gradual exhaustion of mine resources, and the development of mineral processing technology, the issue of tailings reprocessing technology becomes more and more outstanding.

People realized that "useless" tailings contained huge reused value, such as non-ferrous metals, ferrous metals and non-metallic minerals, etc. If abandoned, that's like monumental treasures were abandoned.

Up to now, China's mine tailings storage has reached 8 billion tons, and the proportion is increasing by 300 million tons yearly.

Statistically, the capacity of gold tailings is up to 500 million tons (gold content is 0.2 to 0.6 g/t)

300 tons gold concentrate (calculated by 260 yuan/t)

Statistically, the amount of iron tailings reaches 2.6 billion tons (average grade is 10% )

410 million tons of iron concentrate (calculated by 800 yuan/t)

Tailings reprocessing technology means higher demands on mining enterprise, especially in tailings test, technological innovation, energy-saving and capital investment. For the majority of mining companies, they can’t afford these huge capital investment and strict technical requirements.

Xinhai usually adopt corresponding improvements according to the actual situation of each mine, such as adding reprocessing equipment to combine with original technology and equipment, establishing reprocessing plant.

What Xinhai provides is a complete set of tailings reprocessing process, including tailings test, plant design, complete equipment manufacturing, commissioning and delivery. The strong cohesion among links greatly improves the integrity of the whole plant.

No same tailings, no same tailings reprocessing process. So, Xinhai always customizes tailings reprocessing technology and equipment for each tailing to achieve the best balance between cost and economic benefits.

Tailings is characterized by poverty, fineness and impurity, especially some refractory tailings. It is difficult to recycle them efficiently with common ore beneficiation technology and equipment, and it is impossible to maximize the recovery of useful minerals.

Many mining enterprises don’t have the ability to treat the whole tailings reprocessing plant, so it is difficult to achieve unity if each link is assigned to different companies.

Besides, many small and medium-sized mining enterprises don’t pay attention to the concept of customization. They believe that the features of same kind of tailing in the same area are roughly the same, so do process and equipment, which give rise to the accidents.

Gold tailings reprocessing

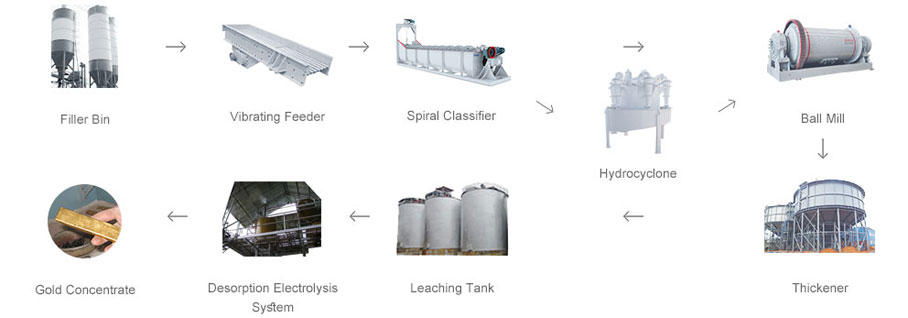

all-slime cyanidation, CIP

Iron tailings reprocessing

magnetic separation, flotation, acid leaching, flocculation

Copper tailings reprocessing

flotation, magnetic separation (recover part of iron ore)

Lead-zinc tailings reprocessing

gravity separation, flotation, magnetic separation, joint process

Phosphate tailings reprocessing

flotation, reverse flotation process used in calcareous phosphate

Inner Mongolia gold mine plant undertaken by Xinhai has been estabished for 40 years. Before the completion of new tailings pond, the amount of old tailings was as high as 900,000 tons, and the gold grade was more than 1g/t on average.

On the basis of the original 250t/d flotation process, Xinhai carried out a series of ore dressing experiment, and decided to adopt all-slime cyanidation CIP technology process according to the characteristics of tailing ore.

| Mineral | Grade of raw ore | Leaching rate | Recovery rate |

|---|---|---|---|

| Gold | 2.83g/t | 86.5% | 80.4% |

According to the preliminary investigation, the amount of gold tailing (gold grade was more than 2.5g/t) was about 380,000 tons, which can be produced for 4-5 years, and the economic profit was over 70 million yuan.

The continuous development and innovation of Xinhai has won countless honors, which is a witness of the continuous progress.

20 Years of Experience

Strong Innovation Power

Thoughtful Customer Service

Please leave your message here! We will send detail technical info and quotation to you!