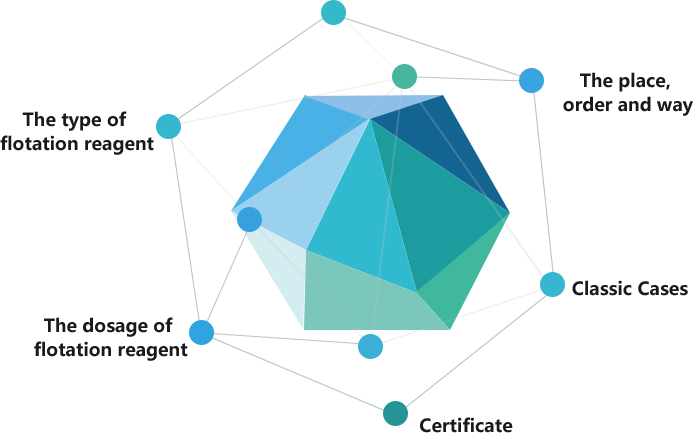

For the flotation process, whether a mineral processing obtains the satisfactory mineral processing indexes depends largely on the flotation reagent system, including the type of flotation reagent, the amount of flotation reagent, the method and location of flotation reagent added. In general, Xinhai helps customers to determine the scientific and reasonable flotation reagents system according to the results of mineral processing test, and continuously adjusts the flotation reagents system in the production, so as to obtain the ideal technical and economic indicators.

◆Content of chemical composition in the ore;

◆Is the ore sulfide or oxide? And the oxidation degree of the sulfide ore;

◆Type, content and particle size of useful minerals and gangue minerals, as well as their dissemination and impregnation characteristics;

◆Distribution of recyclable associated precious metals and dissipated metals.

After grasping the process mineralogical properties of the ore, Xinhai mine research institute will determine its flotation principle. Different flotation principles mean different flotation reagent systems. Based on more than 20 years of mineral processing practice and experience, Xinhai mine research institute has summarized several experiences as follows:

◆Easiness to hardness, that is, float the easy-floating minerals first, then float the difficult-floating minerals. Inhibit the minerals with poor floatability, or inhibit those easy-inhibiting minerals. Do not inhibit those minerals with good floatability and difficult-inhibiting.

◆Less floating and more inhibiting, that is, float the lighter minerals first, and then inhibit the substantial minerals, which is easy to obtain better mineral processing indicators.

◆Float high-value and inhibit low-value, that is, float those high-value minerals and inhibit those low-value minerals, which is easier to achieve the purpose of flotation.

After selecting the floatation principle, Xinhai mine research institute will select the flotation reagent schemes for different floatation cycles one by one, which is required to refer to the practical experience of similar mineral processing plants, and analyze the ore properties, possible flotation schemes, then select the collectors, regulators and foaming agents in turn.

Purpose: Enhance the hydrophobicity and floatability of the mineral

Application:

Sulfide ore: xanthate, aerofloat, diltiazem;

Nonsulfide ore: carboxylic acids, sulfonic acids, sulfuric acid esters, arsonic acid, phosphonic acids, hydroxamic acid, amine

Nonpolar ore: neutral oil (kerosene, diesel)

Purpose: Adjust the effect of collector and medium conditions

Application:

1. Inhibitors: Increase the hydrophilicity of the mineral surface and reduce the floatability of the mineral

Sulfide ore: Lime inhibits used to inhibit pyrite; cyanide inhibits used to inhibit sphalerite, pyrite, chalcopyrite; sulfite used to inhibit sphalerite, pyrite; zinc sulfate used to inhibit sphalerite; dichromate used to inhibit galena;

Nonsulfide ore: Sodium silicate used to inhibit gangue minerals, such as quartz, silicate.

2. Activator: Promote the action of minerals and collectors or remove the inhibiting effect

Copper sulfate, silver nitrate and lead nitrate can be used as activators when the collector is the xanthate;

Calcium chloride and barium chloride can be used as activators when the collector is fatty acid.

3. pH value regulator: Adjust the acidity of pulp

Purpose: Promote the formation of stable foam in the slurry

Classification: Commonly pine oil, terpinol oil, cresol, fatty alcohol.

In the flotation process, Xinhai mine research institute suggests that the appropriate dosage of flotation reagents should be selected according to the results of mineral processing tests. In the actual production, Xinhai mine research institute will adjust the dosage of flotation reagents according to the specific situation if the material composition changes, otherwise the dosage of flotation reagents cannot be changed arbitrarily.

Due to the different ore properties, the dosage range of flotation reagent is also different. Even for the same type of ore, there are also some differences in the formation of ore deposit, so the content of useful minerals and gangue vary, and the dosage of flotation reagent required in the flotation process are also different.

Each flotation reagents usually do not interact with minerals alone, so it cannot be viewed in isolation. For example, the collector and inhibitor often interact in the same system, the activator and inhibitor also interact in the same system.

Collector: Add it to the agitation tank or flotation cell with the foaming agent, while the insoluble collector (such as cresol aerofloat, white catching agent, kerosene) is often added to the grinding mill to promote its dispersion and increase the action time with minerals.

Regulator: Add regulator to the grinding mill firstly, which not only make the inhibitor and collector play the role in the appropriate pulp, but also eliminate some unavoidable ions that are harmful to the flotation effect.

Inhibitor: Inhibitor: Add it to the grinding mill before the collector,which can promote the interaction between the inhibitor and the inhibited minerals early.

Activator: Add it to the agitation tank for mixing with the slurry, which can promote the action between activator and activable minerals.

Usually, Xinhai mine research institute will determine the dosing order according to the situation:

Raw ore: PH regulator - collector - foaming agent.

Inhibited ore: Activator - collector - foaming agent

One-time dosing: Add all the flotation agents in one time before the roughing operation.

Application: Generally, one-time dosing method is suitable for those reagents that are soluble in water, cannot be taken away by the froth and is not easy to react in the pulp, such as lime, soda.

Advantage: high reagent concentration, easy to add.

Several-time dosing: Add the flotation reagents in several times along roughing, concentrating and scavenging. Generally, add 60%~70% of the total amount before the flotation stage, and the rest of reagents is added to the appropriate locations in batches.

Application: Oxidizing, labile and reactive reagents, such as xanthate, sulfur dioxide gas; Reagents that are insoluble in water and can be taken away by the froth, such as oleic acid, aliphatic amine; Reagents required a strict dosage, such as sodium sulfide.

Morocco 500tpd silver ore flotation project

Uganda 720tpd phosphorite ore flotation project

Vietnam 800tpd graphite ore flotation project

Mexico 1500tpd Cu-Pb-Zn, Au and Ag ore dressing project

Xinhai mine research institute and mine design institute have passed CNAS international certification, who have the technical ability of carrying out calibration and testing service according to the relevant international standards. And the feasibility study report issued by Xinhai is recognized by international financial institutions.

Xinhai laboratory has a complete set of modern and advanced equipment, including crushing equipment, fine grinding equipment, roasting equipment, drying equipment, spectrometer, atomic fluorescence spectrometer, atomic absorption spectrophotometer, infrared ore testing equipment, etc.

Xinhai laboratory can conduct tests on various mineral processing methods, such as gravity separation, magnetic separation, flotation, cyanide leaching and adsorption, bacterial oxidation, acid leaching, wet dressing, special dressing, heap leaching, tailings concentration and dry drainage, then determine the technical parameters of each method and provide the reasonable ore dressing process.

Please leave your message here! We will send detail technical info and quotation to you!