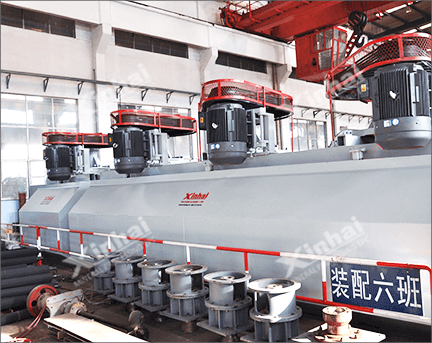

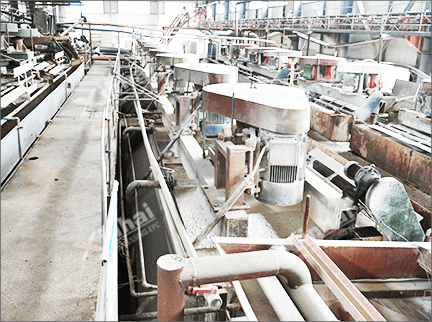

It is reported that more than 90% of non-ferrous metal ores (copper, lead, zinc, etc.) adopt flotation process, especially for those with fine grain and complex symbiosis. Flotation process can achieve ideal separation effect, and separately recover low-grade ore then enrich multiple high-grade concentrates. Different ore properties means different flotation process. According to the dissemination characteristics of metal minerals, Xinhai has determined four kinds of flotation processes:

According to the different flotability and floating speed among copper, lead, zinc ore, Xinhai separately obtains copper concentrate, lead concentrate and zinc concentrate from the slurry.

Simple mineral composition, large differences in flotability among useful minerals, coarse disseminated grain size, high-graded raw ore.

Adapt to the change of ore grade with high flexibility; save flotation reagent.

Xinhai floats copper, lead and zinc minerals together in the mixed concentrate, and dereagents the mixed concentrate then separates, so that the copper, lead and zinc concentrate can be obtained.

Useful minerals are unevenly embedded or associated with each other, or one useful mineral is finely embedded in another mineral, and its coarse coenobium is embedded in gangues.

Good flotation effect; Improve the processing capacity per unit time; Avoid the overgrinding of dissociated useful minerals, which can reduce difficulty of later separation; Save production cost.

Xinhai separates two useful minerals that with similar floatability into the mixed concentrate, and then floats each concentrate. That is, copper sulphide and lead ore with similar floatability are selected as mixed concentrate, and copper and lead is separated. Then the tailings were reactivated to separate the zinc concentrate.

Copper-zinc polymetallic sulfide ore of similar floatability

Process technology matures; easy to control the flotation conditions, combine the strengths of both differential flotation and bulk flotation, widely used in many plants.

With the principle of " easiness to hardness ", Xinhai divides the recovered minerals into two parts: easy-to-float and difficult-to-float according to the difference of natural floatability, and then separate the copper, lead and zinc concentrate from the mixed concentrate.

One of mineral has good floatability, while other minerals can be divided into easy-to-float and difficult-to-float.

Reduce the reagent consumption, avoid the negative effect of excess reagent on flotation result, then improve the flotation indicator.

In general, the most difficulty of the polymetallic sulfide ores separation is the separation among several kinds of ores, especially those low-graded ores with complex embedded features. Therefore, it’s a significant step for separating lead-zinc, copper-zinc, copper-lead to choose right flotation reagents. Xinhai strictly implements the reagent system, controls the dosage of reagent, reduces multiple circulation and loss, then strengthens the flotation effect.

Differential flotation process, floats lead and depresses zinc.

Collectors: Low-level xanthate, advanced xanthate, aerofloat. Separation in alkaline medium.

Inhibitor: CN-、NaCN、kCN、ZnSO4、Na2OS3、Na2S2O3

Differential flotation process, floats copper and depresses zinc. If the separating difficulty is over 2, the depression on zinc should be strengthened.

Collectors: Low-level xanthate, advanced xanthate, aerofloat. Separation in alkaline medium.

Inhibitor: CN-、NaCN、kCN、ZnSO4、Na2OS3、Na2S2O3

Dereagent first, then differential flotation process. Floats copper and depresses lead, or floats lead and depresses copper.

Floats copper and depresses lead: Widely used in secondary copper ore, Cu2+ ions are dissolved too much and bot easy to be inhibited.

Inhibitor: Knox reagent(K2CrO4+KCrO2) combined with Na2S, or oxysulfide.

Floats lead and depresses copper: Widely used in primary copper ore.

Collectors: xanthate, aerofloat. Keep PH value among 9-605, then adjust with CaO.

Inhibitor: cyanide and other inhibitors, or hot dereagent to inhibit lead (40~70℃, and PH value≤7).

Mexico 1500tpd

Au-Ag-xinhai-cu-pb-zn-ore-dressing-process Ore Dressing Project

Columbia 1000tpd

Cu Ore Dressing Project

Laos 500tpd

Au-Cu Ore Dressing Project

Please leave your message here! We will send detail technical info and quotation to you!