JJF Flotation, Wemco Flotation

- 【Introduction】:

- 【 Capacity 】:

- 【Improvement】:

【Advantages】

Large pulp circulation volume up to 2.5 times, is conducive to mineralization of pulp, reagents and air;

Large air suction volume, good dispersion effect;

Reasonable circulation of mineral slurry and the solid particles suspend well, no sediment in tank, and no need to feed mine when it stopped.

Wide range of particle size and high recovery rate of ore selection;

Mechanical agitation; self-air suction but not slurry; ladder is necessary during processing (drop height: 300-400 mm);

It can be combined with model SF as a flotation cells set: model SF as the suction cell and model JJF as the direct flow cell.

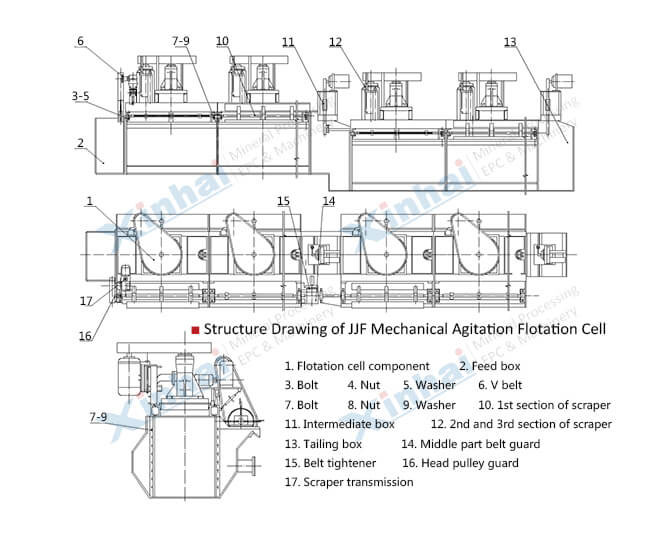

【Product Structure】

JJF type flotation machine is mainly composed of tank body, impeller, stator, dispersing cover, false low, draft tube, vertical tube, adjusting ring. Shallow tank, small diameter, low rotary speed, and low power consumption. Large clearance between impeller and stator, the stator is a cylinder with elliptic hole, and it is good for mixing and dispersing the gas and pulp. The height of stator is lower than impeller, pulp circulation volume is large, and it can be reached at 2.5 times of others. The umbrella-type dispersion cover with holes of the stator can separate the eddy current and bubbles that produced by impeller, so as to keep the pulp surface stable.

【Technical Parameters】

| Model | Effective Volume (m3) |

Capacity (m3/min) |

Impeller Diameter (mm) |

Impeller Revolution (r/min) |

Motor Power for Agitation (kW) | Motor Power for Scraper (kW) | Single Tank Weight (kg) |

| JJF-4 | 4 | 2.0~4 | 410 | 305 | 11 | 1.5 | 2303 |

| JJF-5 | 5 | 2.0~6 | 410 | 305 | 11 | 1.5 | 2416 |

| JJF-8 | 8 | 4.0~12 | 540 | 233 | 22 | 2.2 | 4507 |

| JJF-10 | 10 | 5.0~10 | 540 | 233 | 22 | 1.5 | 4820 |

| JJF-16 | 16 | 5.0~16 | 700 | 180 | 37 | 1.5 | 7657 |

| JJF-20 | 20 | 5.0~20 | 770 | 180 | 45 | 1.5 | 8505 |

【Successful case】

Xinhai made a mineral processing experiments for certain copper plant, chose JJF flotation, wemco flotation as the flotation equipment, adopted 24 JJF-16 flotation cell, six of them are in a series. In order to test the processing capacity of flotation cell, Xinhai made flotation cell series and parallel two kinds of test respectively, after many experiments of the two methods, Xinhai adopted flotation cell series for the copper plant: start two ball mills, the capacity is 110 t/h, the pulp volume is 285.52 m3/h, then the groove surface and bubble volume of JJF flotation cell is suitable, the flotation bubble is normal.